Energy-efficient manufacturing of fibre-based products

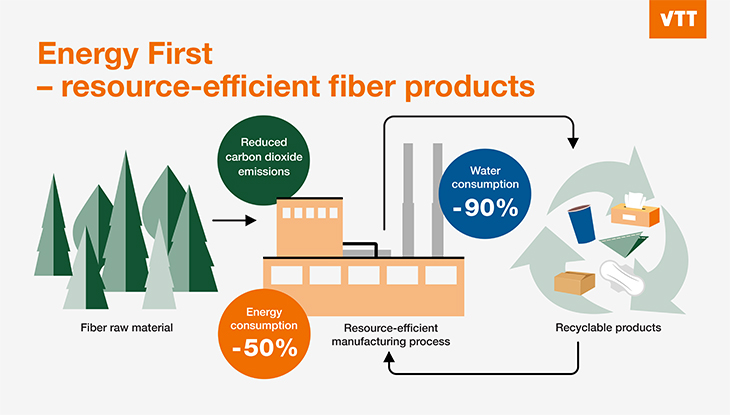

VTT Technical Research Centre of Finland has unveiled a new initiative aimed at tackling the pressing challenges of energy and resource consumption in the forestry and textile industries. The ‘Energy First’ initiative is set to pioneer low-carbon, water-efficient technology that could potentially reduce water usage by up to 90% and energy consumption by over 50%.

With global e-commerce on the rise, the demand for fibre-based packaging solutions is expected to grow by 5–10% annually, according to Statista Market Insights and eMarketer.

This surge necessitates the development of scalable, high-quality, and easily recyclable packaging options that significantly cut carbon footprints. VTT anticipates a substantial shift within non-woven products, such as napkins and wipes, moving away from plastic to cellulose-based alternatives.

Projects, collaborations

The initiative is backed by a budget of approximately 20 million Euros over the next 4 years and will feature several projects, including the establishment of a new open-access pilot line in Jyväskylä, Finland. This collaborative effort aims to develop and test commercially viable, sustainable alternatives for cardboard packaging, hygiene products, and non-woven fabrics.

“This new initiative is a pivotal step towards more sustainable and competitive fibre-based products, and has the potential for great impact, thanks to more than 50 industrial partners,” said Atte Virtanen, Vice-President of Bio-material Processing and Products at VTT.

The forest industry is currently facing challenges, including rising energy costs and fibrewood scarcity. The Energy First initiative aims to address these issues by developing manufacturing processes that minimize both water and energy usage.

Products developed through this initiative will be compatible with existing recycling methods and are designed to provide a sustainable alternative to reusable packaging. The upcoming EU packaging directive mandates that both the raw materials and manufacturing processes must be sustainable, necessitating sustainability assessments for recyclable bio-based packaging solutions.

In addition to enhancing environmental sustainability, the project seeks to redefine the forest industry’s impact and improve the competitiveness of fibre-based products. By producing lighter products, more items can be generated from the same amount of wood, enhancing resource efficiency.

Renewable materials

Sampo Immonen, R&D Director at Valmet, noted, “The ‘Energy First’ project has several captivating work packages that align closely with Valmet’s current research and development objectives, particularly in energy efficiency and novel fibre-based structures.”

Whether in textiles, construction, or energy storage, entire industrial value chains can profitably utilise renewable and reusable materials, aided by scientific advancements. The focus is on creating sustainable materials derived from renewable resources like wood and agricultural byproducts, ensuring that recycling and reusability are integral to the research process.

Atte Virtanen highlighted innovative developments, such as stretchable paperboard that can be recycled alongside traditional paper, demonstrating advancements in material production that conserve natural resources.

By 2030, industries in packaging, composites, chemicals, and textiles are expected to fully embrace bio-based materials, phasing out fossil raw materials and plastics in favour of high-value, renewable, recyclable options.

Comments

- ‘Red gazelle’ makes window installation easy

- Felder’s solutions for window and door production

- Versatile sliding-folding systems from Hafele

- Door line automation from Woodtech Consultants

- Accutec solutions for uPVC windows

- Jowat’s VOC-free primer for window profile wrapping

- Flexible solutions for doors, windows from SCM

- Tostem introduces Giesta steel doors; calls for dealers

- Folder system by Salice optimises cabinet space

- Turakhia has top-quality veneers for doors

- Mirka has solutions for difficult sanding of doors

- When Lamello’s Cabineo became a game changer

- Digital lacquer embossing for flooring from Hymmen

- Weber sanders help achieve luxury surfaces

- Rehau has designs on growing edge band market

- Samet ties up with Greenply to tap Indian hardware market

- IMA Schelling sets up base in India

- Hettich earns BIS nod for hinges, runners

- Biesse India now a Multi-Material Expert

- The importance of selecting the correct tools

- Indian cabinet maker shines at Lyon WorldSkills

- ‘Collaboration holds the key to success’

- Fibreboard recycling becomes a reality

- MumbaiWood now a recognised destination

- Knock on wood: A bouquet of training courses!

- Ligna 2025: ‘Thinking in circles’

- CIFF-Shanghai focuses on furniture design

- Felder hosts in-house show, Technology Days

- Interzum Forum Italy makes impressive debut

- Koelnmesse ties up for 3-in-1 Jakarta fair

- WOFX: a global hub for innovation and growth

- Events Calendar: industry fairs you must visit

- 3D is printing sustainable housing solutions

- Hard or soft? Researchers discover new wood type

- Master, apprentices take AHEC’s cherry challenge

- ‘Zero-to-launch’ modularity transforming hospitality

- ICA’s Urban Matter is about satin-finish metal effect

- MTC’s ‘Woven timbers’ create waves

- Impact of material in interior design

- Underestimated danger: Sharp edges

- Playing safe on clothing storage units

- ‘Green’, 3D-printed panel floors it!

- Adhesive-free joining of wood, metal

- Energy-efficient manufacturing of fibre-based products

- Rice bran wax: a sustainable alternative

- Dual-side hand sanding block has unique features

- Bio-based products for sustainable development

- ‘Wood Vaulting’ may enhance CO2 sequestration

- Protecting forests through advanced AI

- Forest certification benefits wildlife too!

- Elizure, the Rolls Royce of laminates!

- Rehau unveils new Rauvisio Riviera collection

- Hawa Concepta III: upgrade to seamless functional doors

- Hafele’s RE-Twist locks in on security

- Optimus machines feature tomorrow’s technology today

- Merino unveils cutting-edge offerings

- Ornare launches new premium laminates

- New nesting models from SCM

- Advanced moulder, membrane press from Woodtech

- Greenlam Laminates unveils exclusive display centre in Pune

- EUDR implementation dates may be deferred

- Herman Miller introduces bamboo upholstery

- Altendorf named ‘Brand of the Century’

- Catas to verify its test reports

- Combilift wins two prestigious awards

- Holz-Her management transition

- Replica of the Oval Office opens

- Ozone Blu sets up experience centre

- SCM opens new subsidiary in Slovenia

- VDMA faces business stagnation

- RentoMojo reports strong growth in FY24

- Century Plyboards on expansion mode

- Subhra named DG of FSC

- Meta to assist Skill India Mission

- Sugatsune opens Bengaluru experience centre

- Dieffenbacher acquires Pagnoni

- Pepperfry partners with Infra.Market

- Hafele opens light store in Chandigarh