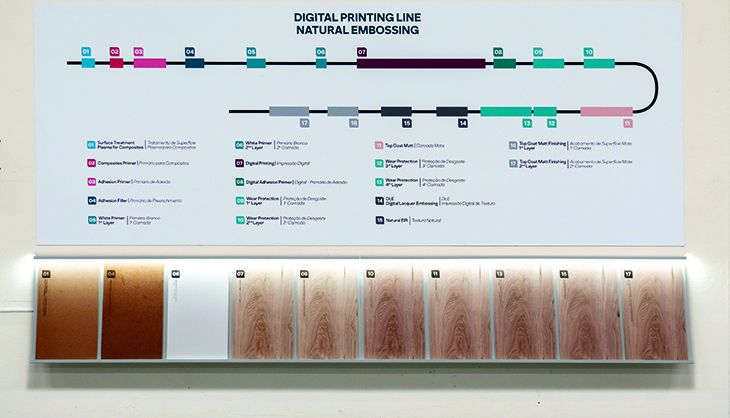

Digital lacquer embossing for flooring from Hymmen

Hymmen GmbH’s digital lacquer embossing technology in action during the production process at Amorim.

Hymmen GmbH Maschinen-und Anlagenbau, based in Bielefeld (Germany), is known for its innovative solutions and has now solidified its reputation as a key player in the digital printing technology sector.

The company recently partnered with Amorim Cork Flooring, a market leader in sustainable cork flooring and wall decorations, to commission a new production line at Amorim’s Porto (Portugal) site for enhancing its production capabilities.

Hymmen’s Jupiter digital printing line is at the heart of Amorim’s new production setup. This line, along with the DLE-plus (digital lacquer embossing) technology, was implemented swiftly and efficiently.

Unlimited flexibility

The digital printing technology is pivotal for the future of flooring due to its unlimited design flexibility and ability to cater to a wide range of materials. This technology supports faster market responses, reduces material waste, and lowers process costs while enhancing market differentiation.

To ensure widespread access to their advanced digital printing technologies, Hymmen has partnered exclusively with i4F. This collaboration promotes Hymmen’s strong digital printing intellectual property portfolio, including their DLE technology that delivers highly realistic optics and haptics, setting a new standard in the industry.

Jupiter JPT-C digital single pass machine is designed for 24x7 industrial production and features a high-precision continuous substrate conveyor for maximum register accuracy. It operates at printing speeds of 25-50 metres per minute and offers an optical resolution exceeding 1000 DPI.

The Jupiter line ensures the highest colour stability and print quality. Additionally, the DLE technology creates embossed-in-register (EIR) structures that perfectly match the surface decor.

This enhances surface performance while maintaining core lacquer properties such as hardness, bonding, scratch resistance, and chemical reliability.

This ambitious project culminated in the first digitally printed cork flooring being scheduled for market introduction in January 2024. Fernando Melo, CEO of Amorim Cork Flooring, said: “We are confident that this state-of-the-art technology, which allows us to produce flooring with fantastic decors and intense, well-defined structures, will keep us a step ahead in the market.”

The successful implementation of Hymmen’s advanced digital printing technology at Amorim marks a significant milestone in the flooring industry, showcasing the potential for future innovations and collaborations.

Comments

- ‘Red gazelle’ makes window installation easy

- Felder’s solutions for window and door production

- Versatile sliding-folding systems from Hafele

- Door line automation from Woodtech Consultants

- Accutec solutions for uPVC windows

- Jowat’s VOC-free primer for window profile wrapping

- Flexible solutions for doors, windows from SCM

- Tostem introduces Giesta steel doors; calls for dealers

- Folder system by Salice optimises cabinet space

- Turakhia has top-quality veneers for doors

- Mirka has solutions for difficult sanding of doors

- When Lamello’s Cabineo became a game changer

- Digital lacquer embossing for flooring from Hymmen

- Weber sanders help achieve luxury surfaces

- Rehau has designs on growing edge band market

- Samet ties up with Greenply to tap Indian hardware market

- IMA Schelling sets up base in India

- Hettich earns BIS nod for hinges, runners

- Biesse India now a Multi-Material Expert

- The importance of selecting the correct tools

- Indian cabinet maker shines at Lyon WorldSkills

- ‘Collaboration holds the key to success’

- Fibreboard recycling becomes a reality

- MumbaiWood now a recognised destination

- Knock on wood: A bouquet of training courses!

- Ligna 2025: ‘Thinking in circles’

- CIFF-Shanghai focuses on furniture design

- Felder hosts in-house show, Technology Days

- Interzum Forum Italy makes impressive debut

- Koelnmesse ties up for 3-in-1 Jakarta fair

- WOFX: a global hub for innovation and growth

- Events Calendar: industry fairs you must visit

- 3D is printing sustainable housing solutions

- Hard or soft? Researchers discover new wood type

- Master, apprentices take AHEC’s cherry challenge

- ‘Zero-to-launch’ modularity transforming hospitality

- ICA’s Urban Matter is about satin-finish metal effect

- MTC’s ‘Woven timbers’ create waves

- Impact of material in interior design

- Underestimated danger: Sharp edges

- Playing safe on clothing storage units

- ‘Green’, 3D-printed panel floors it!

- Adhesive-free joining of wood, metal

- Energy-efficient manufacturing of fibre-based products

- Rice bran wax: a sustainable alternative

- Dual-side hand sanding block has unique features

- Bio-based products for sustainable development

- ‘Wood Vaulting’ may enhance CO2 sequestration

- Protecting forests through advanced AI

- Forest certification benefits wildlife too!

- Elizure, the Rolls Royce of laminates!

- Rehau unveils new Rauvisio Riviera collection

- Hawa Concepta III: upgrade to seamless functional doors

- Hafele’s RE-Twist locks in on security

- Optimus machines feature tomorrow’s technology today

- Merino unveils cutting-edge offerings

- Ornare launches new premium laminates

- New nesting models from SCM

- Advanced moulder, membrane press from Woodtech

- Greenlam Laminates unveils exclusive display centre in Pune

- EUDR implementation dates may be deferred

- Herman Miller introduces bamboo upholstery

- Altendorf named ‘Brand of the Century’

- Catas to verify its test reports

- Combilift wins two prestigious awards

- Holz-Her management transition

- Replica of the Oval Office opens

- Ozone Blu sets up experience centre

- SCM opens new subsidiary in Slovenia

- VDMA faces business stagnation

- RentoMojo reports strong growth in FY24

- Century Plyboards on expansion mode

- Subhra named DG of FSC

- Meta to assist Skill India Mission

- Sugatsune opens Bengaluru experience centre

- Dieffenbacher acquires Pagnoni

- Pepperfry partners with Infra.Market

- Hafele opens light store in Chandigarh