Richfill calibrated filler solves multiple problems

Plywood manufacturers constantly strive to produce top-quality products that meet international standards. Despite investing in premium raw materials, skilled labour, and advanced processes, challenges such as air lines on face veneer, surface delamination, glue stains, weak core bonds, and air bubbles continue to affect production.

These defects not only impact the structural integrity and aesthetics of plywood but also lead to material wastage, increased costs, and dissatisfied customers. Addressing these issues efficiently is crucial to maintaining profitability and a strong market reputation.

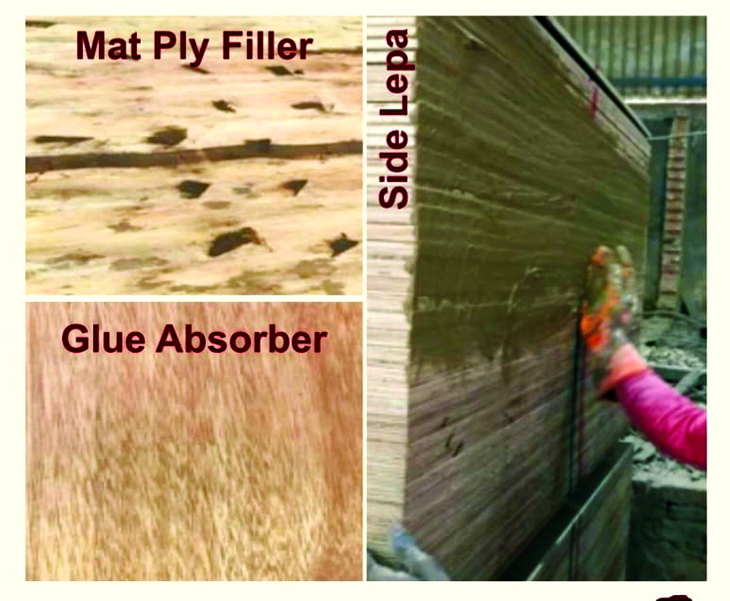

Richfill Calibrated Filler provides a simple yet highly effective solution to these common manufacturing problems. By adding a small percentage to the glue line, manufacturers can significantly improve both core-to-core and core-to-face bonding, ensuring a stronger plywood structure with fewer glue spots and air lines.

This improvement translates into better durability, reduced rejection rates, and enhanced product consistency. When used in mat putty, Richfill creates a smooth, weave-free surface, eliminating air pockets and ensuring a flawless finish. Additionally, plywood side lepa prepared with Richfill remains intact and does not shrink or detach, even during transportation, preventing one of the major concerns for manufacturers.

Many plywood manufacturers who have adopted Richfill Calibrated Filler in their production process report significant quality improvements while keeping costs under control. Face delamination caused by excess glue, scratches, or weak bonding is noticeably reduced, ensuring better consistency and long-term performance.

The optimized glue application also minimizes wastage, leading to a more efficient production cycle. With fewer defects and reduced material loss, manufacturers can maximize output while lowering overall production costs.

Richfill’s benefits extend beyond just improving plywood quality. Its use enhances process efficiency, saving manufacturers time, effort, and resources while eliminating recurring production issues. This multipurpose additive is a strategic investment that boosts both productivity and product value, giving plywood manufacturers a competitive edge in the market.

Discover the transformative power of Richfill Calibrated Filler in Hall 9, Booth A1-09.

Comments

- In Silver Jubilee year, propelling growth remains the ‘mantra’

- PHANTOM HANDS

- ‘Fevicol Pro series is disruptive innovation’

- Furtech Show 2025 returns to Dubai in September

- Vert: the red-oak route to a cool-cool city

- Moisture? Measure twice, cut once!

- ‘Mirka has solutions for today, tomorrow, thereafter’

- On 50th anniversary, Ligna has more on offer

- Ukrainian designer redefines function through form

- New technology holds key to plywood industry survival

- Light on solid wood’s role in neuro-diverse spaces

- Evolving furniture demands require ace tooling

- Interzum 2025: rethinking resources

- CIFF Guangzhou opens in March in two phases

- Feria Hábitat València to expand into design

- WOFX 2024 was an unprecedented success

- HIFF 2025 promises to be bigger, better

- Event-Calendar

- Hettich’s ‘Magic lights’ are sheer brilliance

- Blum’s Revego systems for new space concepts

- Häfele’s MatrixBox combines functionality, sophistication

- How Protego’s oils protect exterior woodwork

- Ineos adds new ABS grade

- 2025 outlook for laminate industry

- A functional masterpiece of garden architecture

- European symposium highlights formaldehyde emission limits

- Egger adopts holistic approach to waste management

- Role of PUR adhesives in flat lamination

- Weber machines dovetail into best practices

- Hymmen’s smart2i facilitates digitally mapping production

- Schmalz compact ejectors lead ‘green’ automation

- Arnavi introduces Rema FX 250 table saw

- HAKS helps with design, tech, training

- Transforming woodworking with precision and efficiency

- ‘Cannot miss’: IWMMTA programme for industry

- Premium woodworking machinery from Jai

- High-tech drilling machine, planer sander from Woodtech

- Innovation defines Turakhia products

- Intelligent door production lines from Aadhunik

- Aryamman introduces two exquisite new décors

- Biesse’s Rover Edge revolutionises edge banding

- Check out versatile, durable Canadian wood species

- Expert slide machinery manufacturer from Taiwan

- Ebco to unveil more functional fittings

- Felder to showcase its range of woodworking machinery

- Frontaline has honeycomb core for shutters

- Holytek remains finger-jointing champion

- Homag to showcase its latest innovations

- ICA Pidilite: defining the future of wood coatings

- Innovator’s veneer splicers are UltiMate

- Premium quality steel belts from IPCO

- Precision solutions from Jacinth Machineries

- UV flatbed printers for furniture, interiors

- NextGen sanding tools from Mirka

- Pro-grade edge bander from OAV

- Check out the new Ornare ‘Surface’ range

- AM15K laminates meet new design challenges

- Richfill calibrated filler solves multiple problems

- SCM to present cutting-edge technologies

- Double-side tenoners, profilers from Technik

- Weinig’s Timbermat 5 is versatile planer, moulder

- Woodmaster’s machines ensure precision and efficiency

- Dieffenbacher’s ‘Osiris’ set to revolutionise fibreboard recycling

- Ebco Led lighting feature

- Jovas Tech Solutions – Redefining Woodworking Technology in India

- ITP: Crafting Excellence, Transforming Spaces

- “Greenlam Studio opens in Nashik”

- Dew River Group: Innovating Sustainable Wood Solutions

- Woodtech: Pioneering Advanced Woodworking Solutions in India