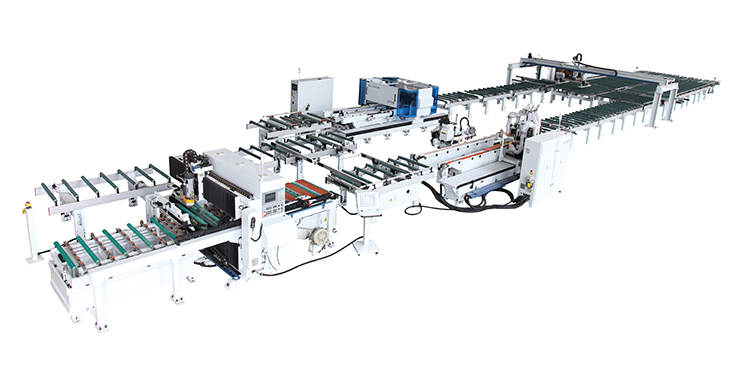

Intelligent door production lines from Aadhunik

The Indian furniture manufacturing sector is moving towards automated plants with software, artificial intelligence (AI) for mass production, with quality control systems to match global standards.

Intelligent door production lines are revolutionising the industry by incorporating advanced technologies such as automation, robotics, and AI. These lines are designed to optimise production processes, enhance efficiency and improve overall product quality.

With these lines we can produce up to 500 doors and door frames per shift. Some of these key components and technologies are:

• Automated material handling: Robotic arms and automated guided vehicles (AGVs) handle raw materials, components, and finished products, minimizing manual labour and reducing the risk of human error.

• CNC machining centres: Computer numerical control machines precisely cut, shape and drill door components with high accuracy and repeatability.

• Robotic assembly: Robots assemble door frames, panels, and hardware, ensuring consistent quality and reducing labour costs.

• AI-powered quality control: AI-powered vision systems and sensors inspect doors at various stages of production, identifying defects and ensuring adherence to quality standards.

• IoT connectivity: Internet of Things sensors and devices monitor equipment performance, track production progress, and provide real-time data for predictive maintenance and process optimization.

Among the benefits of intelligent door production lines are increased efficiency, reducing lead times and increasing output. Consistent and precise manufacturing processes minimize defects and ensure high-quality products.

It reduces labour costs, minimizes material waste, and optimizes energy consumption. Automation eliminates the need for manual handling of heavy materials, reducing the risk of workplace injuries.

Intelligent lines can be easily re-configured to accommodate different door designs and production volumes, adapting to changing market demands.

Pune-based Aadhunik Woodworking Machinery (AWM) offers smarter, greener and efficient door and door frame production facilities, from stand-alone equipment to totally automated lines.

Aadhunik offers process consultation, machinery selection, layout, hardware and software for quality control and management information system. For these lines we have European and Chinese options, both backed by strong, well trained service support.

Aadhunik also offers state-of-the-art technology and value addition for flat lamination systems, UV coating lines, automatic spraying machine, and profile wrapping solutions. For more information, write to praveendhore@gmail.com.

Comments

- In Silver Jubilee year, propelling growth remains the ‘mantra’

- PHANTOM HANDS

- ‘Fevicol Pro series is disruptive innovation’

- Furtech Show 2025 returns to Dubai in September

- Vert: the red-oak route to a cool-cool city

- Moisture? Measure twice, cut once!

- ‘Mirka has solutions for today, tomorrow, thereafter’

- On 50th anniversary, Ligna has more on offer

- Ukrainian designer redefines function through form

- New technology holds key to plywood industry survival

- Light on solid wood’s role in neuro-diverse spaces

- Evolving furniture demands require ace tooling

- Interzum 2025: rethinking resources

- CIFF Guangzhou opens in March in two phases

- Feria Hábitat València to expand into design

- WOFX 2024 was an unprecedented success

- HIFF 2025 promises to be bigger, better

- Event-Calendar

- Hettich’s ‘Magic lights’ are sheer brilliance

- Blum’s Revego systems for new space concepts

- Häfele’s MatrixBox combines functionality, sophistication

- How Protego’s oils protect exterior woodwork

- Ineos adds new ABS grade

- 2025 outlook for laminate industry

- A functional masterpiece of garden architecture

- European symposium highlights formaldehyde emission limits

- Egger adopts holistic approach to waste management

- Role of PUR adhesives in flat lamination

- Weber machines dovetail into best practices

- Hymmen’s smart2i facilitates digitally mapping production

- Schmalz compact ejectors lead ‘green’ automation

- Arnavi introduces Rema FX 250 table saw

- HAKS helps with design, tech, training

- Transforming woodworking with precision and efficiency

- ‘Cannot miss’: IWMMTA programme for industry

- Premium woodworking machinery from Jai

- High-tech drilling machine, planer sander from Woodtech

- Innovation defines Turakhia products

- Intelligent door production lines from Aadhunik

- Aryamman introduces two exquisite new décors

- Biesse’s Rover Edge revolutionises edge banding

- Check out versatile, durable Canadian wood species

- Expert slide machinery manufacturer from Taiwan

- Ebco to unveil more functional fittings

- Felder to showcase its range of woodworking machinery

- Frontaline has honeycomb core for shutters

- Holytek remains finger-jointing champion

- Homag to showcase its latest innovations

- ICA Pidilite: defining the future of wood coatings

- Innovator’s veneer splicers are UltiMate

- Premium quality steel belts from IPCO

- Precision solutions from Jacinth Machineries

- UV flatbed printers for furniture, interiors

- NextGen sanding tools from Mirka

- Pro-grade edge bander from OAV

- Check out the new Ornare ‘Surface’ range

- AM15K laminates meet new design challenges

- Richfill calibrated filler solves multiple problems

- SCM to present cutting-edge technologies

- Double-side tenoners, profilers from Technik

- Weinig’s Timbermat 5 is versatile planer, moulder

- Woodmaster’s machines ensure precision and efficiency

- Dieffenbacher’s ‘Osiris’ set to revolutionise fibreboard recycling

- Ebco Led lighting feature

- Jovas Tech Solutions – Redefining Woodworking Technology in India

- ITP: Crafting Excellence, Transforming Spaces

- “Greenlam Studio opens in Nashik”

- Dew River Group: Innovating Sustainable Wood Solutions

- Woodtech: Pioneering Advanced Woodworking Solutions in India