Premium woodworking machinery from Jai

Jai Industries offer an unparalleled array of products that include woodworking and panel processing machinery and electric motors. It is well known for its engineering quality, technology and innovation.

Its range of machines are products of R&D backed, high-end precision engineering and have the best possible features and are made of the topmost quality material and components. All the products are backed by dedicated service and guidance. Its machines are specifically produced to suit Indian working conditions that ensure performance and operating comfort.

The Optimus series comprise a range of solid wood machinery in the premium segment and have high-end features that are specially developed for units engaged in solid wood-craft business.

OptiBore 6.12

This is a - 6 side CNC boring routing center with bar code reader.

Salient Features

• Finishes six sides boring and top/bottom routing or grooving operation in one-time, full automatically.

• Sturdy built heavy-duty machine made to suit Indian working conditions for precise boring and routing application.

• High-performance machine with high feeding speed gives more production.

• Structure is made after annealing aging treatment for long term stability.

• Upper spindle equipped with saw blade for horizontal slot.

• Two panels mirror processing can be done simultaneously.

• Two bottom spindles for two types of milling work in one process.

• All 3 spindles with 6 kw.

• Grippers are controlled by servo motors for high accuracy.

• Intelligent auto side aligner that positions the board from the side tightly to ensure precise gripping.

• Air tank provided for stable pressure during working.

• Processing files can be uploaded automatically by scanning bar code and generating NC program for processing.

• Supporting DXF file from CAD Software.

• Ensuring longer machine life, safe operation, reduced unscheduled downtime and more economical operation costs.

• Low maintenance m/c, easily available cost-effective spares, best service support.

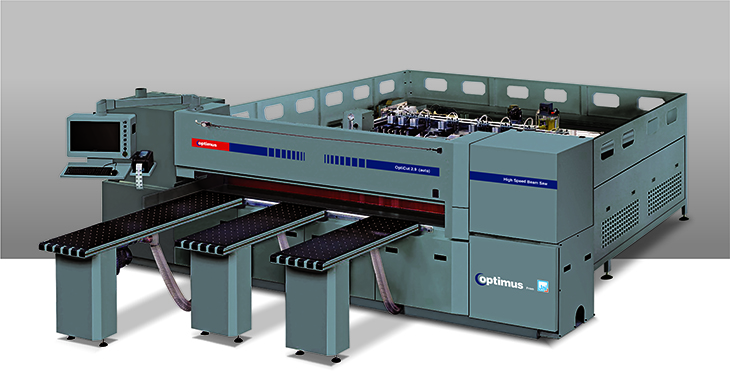

OptiCut 2.9 (auto)

This is a high-speed beam saw with optimization software, label printer and air floating table.

Salient Features

• Robust, balanced, fast & heavy duty saw carriage unit with servo motor ensuring maximum stability. Specially designed technologies to guarantee precision & rigidity.

• Constant high performance in industrial continues production.

• Cutting optimization software is simple to use & gives precise operation with maximum productivity.

• Steel ball air-floating table, avoiding scratches on board and assuring smooth board movement.

• Pneumatic side aligner, integrated with the saw carriage, can perfectly align given thin or flexible panel, reducing cycle cutting time.

• Intelligent lifting of saw blade up to 100 mm.

• Minimum panel size 30 x 50 mm can be cut.

• Saw carriage speed can be adjusted from 0 - 100 m / min

• Independent motors for main saw and scoring.

• Easy change of saw blades.

• Automatic lubrication system ensures efficient operation and increase life of parts.

UltraEdge 7.7P

UltraEdge 7.7P is a high-speed auto edge bander

Salient Features

• Complete stability even at maximum feeding speed of 25 m/min due to robust machine structure.

• User friendly 15” Smart Touch PLC control panel.

• 6 Pressure Rollers with Scraper for perfect pressing.

• Combination of rough & fine trimming unit enables better finish on edge.

• Diamond cutters for pre-milling & trimming.

• Heavy-duty pillar type 2 motor round cornering unit.

• Glue scrapping unit for ultra-fine finish.

• Clip-out unit to remove scrapping waste.

• Small support rollers provided for better stability on panel with holes.

• Encoder for edge banding tape measurement Overall meter run (OMR) & Project meter run (PMR).

• Heavy-Duty Gear Box & Motor for conveyor.

• Motorized up-down movement of pressure beam for easy thickness setting for quick operation from control panel.

• Automatic lubrication system circulates lubrication to the required parts of the machine, ensures efficient operation and increase life of parts.

• Safety Air Tank provision for non-dropping of air during process.

Comments

- In Silver Jubilee year, propelling growth remains the ‘mantra’

- PHANTOM HANDS

- ‘Fevicol Pro series is disruptive innovation’

- Furtech Show 2025 returns to Dubai in September

- Vert: the red-oak route to a cool-cool city

- Moisture? Measure twice, cut once!

- ‘Mirka has solutions for today, tomorrow, thereafter’

- On 50th anniversary, Ligna has more on offer

- Ukrainian designer redefines function through form

- New technology holds key to plywood industry survival

- Light on solid wood’s role in neuro-diverse spaces

- Evolving furniture demands require ace tooling

- Interzum 2025: rethinking resources

- CIFF Guangzhou opens in March in two phases

- Feria Hábitat València to expand into design

- WOFX 2024 was an unprecedented success

- HIFF 2025 promises to be bigger, better

- Event-Calendar

- Hettich’s ‘Magic lights’ are sheer brilliance

- Blum’s Revego systems for new space concepts

- Häfele’s MatrixBox combines functionality, sophistication

- How Protego’s oils protect exterior woodwork

- Ineos adds new ABS grade

- 2025 outlook for laminate industry

- A functional masterpiece of garden architecture

- European symposium highlights formaldehyde emission limits

- Egger adopts holistic approach to waste management

- Role of PUR adhesives in flat lamination

- Weber machines dovetail into best practices

- Hymmen’s smart2i facilitates digitally mapping production

- Schmalz compact ejectors lead ‘green’ automation

- Arnavi introduces Rema FX 250 table saw

- HAKS helps with design, tech, training

- Transforming woodworking with precision and efficiency

- ‘Cannot miss’: IWMMTA programme for industry

- Premium woodworking machinery from Jai

- High-tech drilling machine, planer sander from Woodtech

- Innovation defines Turakhia products

- Intelligent door production lines from Aadhunik

- Aryamman introduces two exquisite new décors

- Biesse’s Rover Edge revolutionises edge banding

- Check out versatile, durable Canadian wood species

- Expert slide machinery manufacturer from Taiwan

- Ebco to unveil more functional fittings

- Felder to showcase its range of woodworking machinery

- Frontaline has honeycomb core for shutters

- Holytek remains finger-jointing champion

- Homag to showcase its latest innovations

- ICA Pidilite: defining the future of wood coatings

- Innovator’s veneer splicers are UltiMate

- Premium quality steel belts from IPCO

- Precision solutions from Jacinth Machineries

- UV flatbed printers for furniture, interiors

- NextGen sanding tools from Mirka

- Pro-grade edge bander from OAV

- Check out the new Ornare ‘Surface’ range

- AM15K laminates meet new design challenges

- Richfill calibrated filler solves multiple problems

- SCM to present cutting-edge technologies

- Double-side tenoners, profilers from Technik

- Weinig’s Timbermat 5 is versatile planer, moulder

- Woodmaster’s machines ensure precision and efficiency

- Dieffenbacher’s ‘Osiris’ set to revolutionise fibreboard recycling

- Ebco Led lighting feature

- Jovas Tech Solutions – Redefining Woodworking Technology in India

- ITP: Crafting Excellence, Transforming Spaces

- “Greenlam Studio opens in Nashik”

- Dew River Group: Innovating Sustainable Wood Solutions

- Woodtech: Pioneering Advanced Woodworking Solutions in India