Industrial-grade tools for modern manufacturing

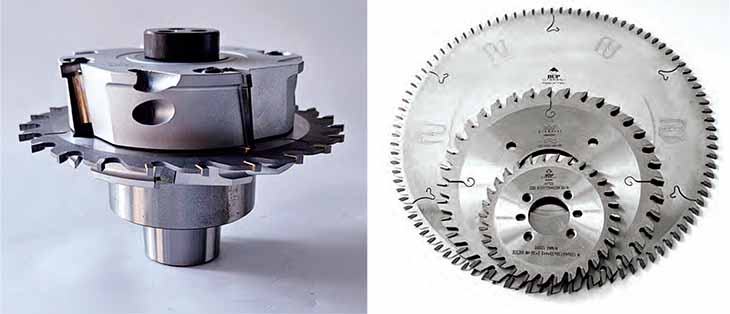

(L-R) Planer tool, circular saw blades and profile and counter-profile tool.

The door manufacturing sector in India is experiencing significant transformation, with the industry increasingly embracing automation. Typical factories are designed to produce up to 200 doors in an 8-hour shift.

To achieve this sustainably while maintaining quality standards and ensuring satisfactory profit margins, it is essential to establish effective synergy between machinery and tools.

It is important to choose the correct circular saw blades for door manufacturing operations, with different blade types serving specific purposes in the production process. An important factor is tooth geometry. The most popular geometries are alternate bevel (ATB) and trapezoidal flat (FZTR or TCG).

ATB is the preferred geometry for ripping and cross cutting. Use a blade with rakers in case you need to rip wet wood. FZTR/ TCG is the preferred geometry for laminated panels.

Fire doors will have one or more layers of calcium silicate or similar material. Due to its abrasive nature, calcium silicate causes higher wear and tear of the tips.

It is recommended to use either PVDF coated blades or PCD blades for fewer interruptions during production.

Precision shaping

Milling is an important operation during the production of doors. Common operations include four-side sizing (also known as formatting); rebate door groove cutting and profile shaping; fire door precision cutting for intumescent strip channels; lock and hinge mortising operations; and door closer and drop seal grooving.

There are multiple options for milling tools. Some of the most popular are:

• Replaceable TC knives. These can be either straight or in a “compression” form for excellent finish on top and bottom.

• Solid carbide tools (1, 2 or 3 spirals) are also very common. These can have chip breakers which are especially useful for deep cuts like lock body mortising.

• PCD tools are chosen for the exceptional life they provide. It would also be helpful to choose the right tool holder.

• Conventional chucks which have a chuck, collet and lock nut are popular due to their low cost and flexibility. However, they can have a higher run out (10-20 µm) and hence feed speed and/or quality could be compromised. If you must choose these chucks, invest in high precision collets. Remember to replace collets at regular intervals.

• Hydro chucks using oil for locking provide excellent stability (runout under 3 µm) and flexibility, but their upfront costs are much higher than standard chucks.

• Shrink fit chucks provide high quality with runout under 3 µm and are cost-effective, but require special tools for operation, limiting flexibility.

Runout significantly affects dimensional accuracy when using small or long tools. Minimizing runout improves tool life, reduces spindle wear, and can extend tool life by up to 60% when limited to 3-5 µm.

Profile shaping

Four-side molders require specialised cutting tools that can simultaneously shape all four sides of door frames. These machines utilise cutterheads with indexable carbide inserts that provide consistent cutting performance and easy maintenance. The typical setup includes:

• Horizontal spindles (top and bottom) with cutting circle diameters ranging from 112mm to 200mm and length of 230 mm. First horizontal spindle is used for creating a reference. Subsequent horizontal spindles could be used either for grooving (grooves for intumescent strip or profiles) or for giving the final finish.

• Vertical spindles (left and right) typically have a cutting circle diameter between 100-200mm and a length of 100-140 mm. They are used for edge profiling or grooving for rubber beadings.

• It is quite common for customers to use a saw blade to retrieve the beading patti from the door frame. This operation uses a tool that combines a planer and a saw blade.

The four-side molder operation requires precise coordination of multiple cutting heads, each powered by independent motors ranging from 5 HP to 10 HP. These machines can process door components with working widths from 25mm to 230mm and thicknesses from 8mm to 120mm.

Door frame tools (L-R) on Powerlock, multi-profile door tools for CNC, and PCD door frame tool.

Door frames

Tenoning machines utilise specialized cutting assemblies that include saw blades, dado heads, and purpose-built tenoning cutters. Modern CNC tenoning machines offer parametric programming capabilities, allowing for precise tenon cutting with minimal setup time. Their key features include:

• Carbide cutter blocks for durability and precision

• Adjustable cutting depths from 5mm to 45mm

• Variable spindle speeds from 9,000-18,000 RPM

Double-end tenoning machines can process both ends of door components simultaneously, significantly increasing production efficiency. These machines typically feature continuous revolution cutters around the workpiece, ensuring consistent quality across all cutting angles.

The investment in quality cutting tools is fundamental to achieving the precision, efficiency, and quality standards demanded in today’s competitive door manufacturing market.

As the industry continues to evolve with new materials and manufacturing techniques, the importance of selecting the right tools for each specific application becomes increasingly critical for sustained success.

– The writer is owner of BUP Utensili S.r.l. a leading manufacturer of woodworking tools in Italy for 50 years. For more information, write to info@buputensili.it

Comments

- European symposium highlights formaldehyde emission limits

- Egger adopts holistic approach to waste management

- ‘For customers, our lab is an open book’

- Taiwan’s Woodworking Machinery Industry Captivates Global Media on Opening Day of LIGNA 2025

- Coming of age of sustainability

- Intelligent packing line, sander from Woodtech

- Ornare introduces 5 new leather decors

- Richfill Edge Coat offers safer plywood finishing

- Jai’s Optimus range stays ahead of the curve

- Merino’s Acrolam sets new benchmarks in elegance

- Pytha 3D-CAD: where precision meets production

- Raucarp edge bands: simple, affordable

- Greenlam scores a 1st: High Quality Product Award

- Häfele turns space solutions provider

- Hettich bets on intelligent motion for evolving interiors

- Praveedh taking desi innovation to the global stage

- Turakhia shows off its Natural Veneers range

- Egger continues to ‘inspire, create, grow’

- Blum turns heads with new drawer, hinge systems

- Murubi gives American ash a meaningful life

- AR system makes ‘augmented carpentry’ possible

- Felder converts interior firm’s vision to reality

- Smart manufacturing with ‘intelligent’ tools

- Rites of passage: Craftsmanship complements tech in Indian door manufacturing

- Understanding basics of adhesives and sealants

- FFSC looks back at a decade of purpose

- Industrial-grade tools for modern manufacturing

- AWM ties up with Yeutong to boost production

- KolkataWood opens 12-14 September

- AI transforming wood panel manufacturing

- Interzum Jakarta promises a bonanza

- Expert partner in product, factory planning

- CBD Guangzhou 2025 grew 47%

- SCM hosts ‘Timber Construction Days’

- Events Calendar: Industry Fairs you must visit

- Bio-designed ‘leather’ from scrap tyres?

- HiTorc chipper redefines wood processing

- Cooking ‘veggies’ for protein-based adhesives

- Hafele’s digital locks go smart

- Italy’s Essepigi has special door lines

- Mirka is a revolution in sanding, finishing

- Ozone expands range of door hardware

- Adhesives: best practices, applications, choices

- Weber sanding tech stands up to Swiss precision

- Silent heroes in homes: Blum fittings

- Biesse powers ahead with smarter, greener manufacturing

- Homag’s LCS program ensures smooth operation

- Paged Furniture reclaims the past, shapes the future